Archflow News

The Hidden Cost of Inefficient Buildings

Amada

2nd October 2025

Across a typical commercial or institutional building, 15–30% of total HVAC energy is routinely wasted. The losses don’t come from a single source; they accumulate from small control errors that compound hour by hour—mistimed schedules, drifting setpoints, over-ventilation, heat/cool overlap, and equipment running inefficiently at part-load. Our AI control stack targets these failure modes in real time, delivering double-digit percentage reductions in energy use while maintaining a 95% occupant-comfort compliance band.

Where the Losses Actually Come From

Below are conservative, portfolio-level ranges we commonly observe. Ranges vary by climate, building type, and system design; they’re intended to show how the total “waste budget” builds up.

When we look at where energy is lost inside a building, it rarely comes from one big failure. Instead, it’s dozens of small inefficiencies that keep adding up.

For instance, systems often start earlier than needed or keep running long after the space is empty—what we call schedule drift. At the same time, setpoints can collapse onto each other: heating and cooling fight unnecessarily because no one has widened the deadband.

Then there’s the classic “hidden waste”: heating and cooling happening at the same time. In many buildings, reheat coils warm air that the central plant has just cooled down—completely invisible unless you analyze multiple systems together.

Ventilation is another culprit. Over-ventilating spaces or running faulty economizers means fans and chillers are conditioning far more outside air than required, burning energy without improving comfort.

And finally, the way big equipment is staged matters. Chillers, boilers, and pumps often run inefficiently at part load, or multiple machines cycle on and off instead of staying in their efficient range. The result is wasted kilowatts, worn-out components, and higher maintenance bills.

Put together: it’s routine to find 15–30% of HVAC energy that can be avoided without replacing hardware, simply by operating the assets we already have—properly, continuously, and adaptively.

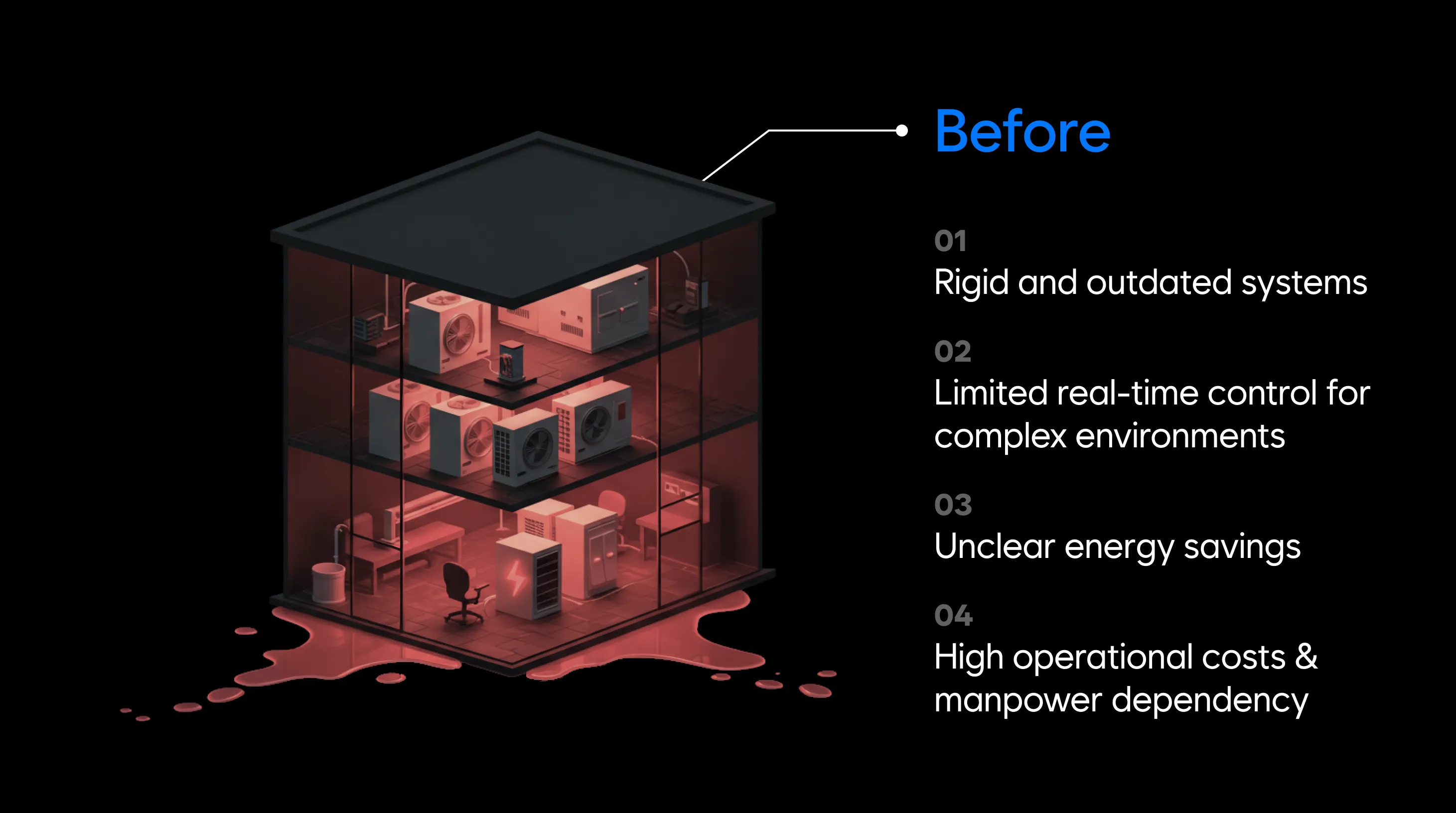

Why Traditional BMS Doesn’t Catch It

A conventional BMS is rule-based: if X then Y. Buildings aren’t. Loads shift with weather, occupancy, internal gains, and system interactions. Local loops (PID at a VAV box) cannot “see” the global optimum (plant, airside, and zones together). Even well-written sequences degrade over time due to sensor drift, manual overrides, and changing space use. Net result: the BMS keeps the building “on,” but not “optimized.”

What Our A-Control Actually Does

1) Multi-Input, Multi-Output Optimization

We coordinate plant ↔ airside ↔ zones simultaneously. The controller ingests streams from temperature/relative humidity/CO₂, valve/damper positions, fan/pump speeds, metering, and weather. It computes control actions that minimize a composite cost function:

- Energy term: kW and kWh, with demand/peak sensitivity

- Comfort term: temperature/RH compliance within a defined band

- Stability term: penalties on excessive actuator movement/short-cycling

2) Forecast-Aware Setpoint Resets

The system predicts near-term loads and resets:

- Supply air temperature & static pressure based on diversity and valve positions

- Chilled/hot water temperatures based on coil approach and zone calls

- Ventilation rates tied to occupancy signals and IAQ targets

- This anticipatory control avoids overshoot and trims part-load losses.

3) Constraint-Safe Policy Learning

We employ a learning controller that is hard-bounded by safety and comfort constraints. It never violates: freeze protection, max/min SAT, equipment limits, or the operator-approved comfort envelope. Learning occurs inside these bounds.

4) Shadow Mode Before Direct Control

Before writing any points, the policy runs in shadow: it proposes actions, we compare against actual outcomes, and only when accuracy and stability meet thresholds do we elevate to closed-loop control. This preserves operations while building site-specific confidence.

Inefficiency in buildings is not an edge case—it’s the norm. Every day, 15–30% of HVAC energy quietly slips away through control gaps that no traditional system can truly catch. That is money lost, capacity wasted, and carbon unnecessarily emitted.

With A-Control, these losses turn into double-digit savings without new equipment, without disruption, and without sacrificing comfort. At scale, this is not a nice-to-have; it is the fastest, most cost-effective path to efficiency that every building operator can justify.

Company

Ground One Inc. 14F, 16 Maehun-ro, Seocho-gu, Seoul, Republic of Korea

+82-02-2277-1110

info@archflow.ai

Products

Blog

Contact

Join us

GroundOne 2025 © Archflow by GrounOne Inc. All rights reserved

Archflow News

The Hidden Cost of Inefficient Buildings

Amada

2nd October 2025

Across a typical commercial or institutional building, 15–30% of total HVAC energy is routinely wasted. The losses don’t come from a single source; they accumulate from small control errors that compound hour by hour—mistimed schedules, drifting setpoints, over-ventilation, heat/cool overlap, and equipment running inefficiently at part-load. Our AI control stack targets these failure modes in real time, delivering double-digit percentage reductions in energy use while maintaining a 95% occupant-comfort compliance band.

Where the Losses Actually Come From

Below are conservative, portfolio-level ranges we commonly observe. Ranges vary by climate, building type, and system design; they’re intended to show how the total “waste budget” builds up.

When we look at where energy is lost inside a building, it rarely comes from one big failure. Instead, it’s dozens of small inefficiencies that keep adding up.

For instance, systems often start earlier than needed or keep running long after the space is empty—what we call schedule drift. At the same time, setpoints can collapse onto each other: heating and cooling fight unnecessarily because no one has widened the deadband.

Then there’s the classic “hidden waste”: heating and cooling happening at the same time. In many buildings, reheat coils warm air that the central plant has just cooled down—completely invisible unless you analyze multiple systems together.

Ventilation is another culprit. Over-ventilating spaces or running faulty economizers means fans and chillers are conditioning far more outside air than required, burning energy without improving comfort.

And finally, the way big equipment is staged matters. Chillers, boilers, and pumps often run inefficiently at part load, or multiple machines cycle on and off instead of staying in their efficient range. The result is wasted kilowatts, worn-out components, and higher maintenance bills.

Put together: it’s routine to find 15–30% of HVAC energy that can be avoided without replacing hardware, simply by operating the assets we already have—properly, continuously, and adaptively.

Why Traditional BMS Doesn’t Catch It

A conventional BMS is rule-based: if X then Y. Buildings aren’t. Loads shift with weather, occupancy, internal gains, and system interactions. Local loops (PID at a VAV box) cannot “see” the global optimum (plant, airside, and zones together). Even well-written sequences degrade over time due to sensor drift, manual overrides, and changing space use. Net result: the BMS keeps the building “on,” but not “optimized.”

What Our A-Control Actually Does

1) Multi-Input, Multi-Output Optimization

We coordinate plant ↔ airside ↔ zones simultaneously. The controller ingests streams from temperature/relative humidity/CO₂, valve/damper positions, fan/pump speeds, metering, and weather. It computes control actions that minimize a composite cost function:

- Energy term: kW and kWh, with demand/peak sensitivity

- Comfort term: temperature/RH compliance within a defined band

- Stability term: penalties on excessive actuator movement/short-cycling

2) Forecast-Aware Setpoint Resets

The system predicts near-term loads and resets:

- Supply air temperature & static pressure based on diversity and valve positions

- Chilled/hot water temperatures based on coil approach and zone calls

- Ventilation rates tied to occupancy signals and IAQ targets

- This anticipatory control avoids overshoot and trims part-load losses.

3) Constraint-Safe Policy Learning

We employ a learning controller that is hard-bounded by safety and comfort constraints. It never violates: freeze protection, max/min SAT, equipment limits, or the operator-approved comfort envelope. Learning occurs inside these bounds.

4) Shadow Mode Before Direct Control

Before writing any points, the policy runs in shadow: it proposes actions, we compare against actual outcomes, and only when accuracy and stability meet thresholds do we elevate to closed-loop control. This preserves operations while building site-specific confidence.

Inefficiency in buildings is not an edge case—it’s the norm. Every day, 15–30% of HVAC energy quietly slips away through control gaps that no traditional system can truly catch. That is money lost, capacity wasted, and carbon unnecessarily emitted.

With A-Control, these losses turn into double-digit savings without new equipment, without disruption, and without sacrificing comfort. At scale, this is not a nice-to-have; it is the fastest, most cost-effective path to efficiency that every building operator can justify.

Company

Ground One Inc. 14F, 16 Maehun-ro, Seocho-gu, Seoul, Republic of Korea

+82-02-2277-1110

info@archflow.ai

Products

Blog

Contact

Join us

GroundOne 2025 © Archflow by GrounOne Inc. All rights reserved

Archflow News

The Hidden Cost of Inefficient Buildings

2nd October 2025

Across a typical commercial or institutional building, 15–30% of total HVAC energy is routinely wasted. The losses don’t come from a single source; they accumulate from small control errors that compound hour by hour—mistimed schedules, drifting setpoints, over-ventilation, heat/cool overlap, and equipment running inefficiently at part-load. Our AI control stack targets these failure modes in real time, delivering double-digit percentage reductions in energy use while maintaining a 95% occupant-comfort compliance band.

Where the Losses Actually Come From

Below are conservative, portfolio-level ranges we commonly observe. Ranges vary by climate, building type, and system design; they’re intended to show how the total “waste budget” builds up.

When we look at where energy is lost inside a building, it rarely comes from one big failure. Instead, it’s dozens of small inefficiencies that keep adding up.

For instance, systems often start earlier than needed or keep running long after the space is empty—what we call schedule drift. At the same time, setpoints can collapse onto each other: heating and cooling fight unnecessarily because no one has widened the deadband.

Then there’s the classic “hidden waste”: heating and cooling happening at the same time. In many buildings, reheat coils warm air that the central plant has just cooled down—completely invisible unless you analyze multiple systems together.

Ventilation is another culprit. Over-ventilating spaces or running faulty economizers means fans and chillers are conditioning far more outside air than required, burning energy without improving comfort.

And finally, the way big equipment is staged matters. Chillers, boilers, and pumps often run inefficiently at part load, or multiple machines cycle on and off instead of staying in their efficient range. The result is wasted kilowatts, worn-out components, and higher maintenance bills.

Put together: it’s routine to find 15–30% of HVAC energy that can be avoided without replacing hardware, simply by operating the assets we already have—properly, continuously, and adaptively.

Why Traditional BMS Doesn’t Catch It

A conventional BMS is rule-based: if X then Y. Buildings aren’t. Loads shift with weather, occupancy, internal gains, and system interactions. Local loops (PID at a VAV box) cannot “see” the global optimum (plant, airside, and zones together). Even well-written sequences degrade over time due to sensor drift, manual overrides, and changing space use. Net result: the BMS keeps the building “on,” but not “optimized.”

What Our A-Control Actually Does

1) Multi-Input, Multi-Output Optimization

We coordinate plant ↔ airside ↔ zones simultaneously. The controller ingests streams from temperature/relative humidity/CO₂, valve/damper positions, fan/pump speeds, metering, and weather. It computes control actions that minimize a composite cost function:

- Energy term: kW and kWh, with demand/peak sensitivity

- Comfort term: temperature/RH compliance within a defined band

- Stability term: penalties on excessive actuator movement/short-cycling

2) Forecast-Aware Setpoint Resets

The system predicts near-term loads and resets:

- Supply air temperature & static pressure based on diversity and valve positions

- Chilled/hot water temperatures based on coil approach and zone calls

- Ventilation rates tied to occupancy signals and IAQ targets

- This anticipatory control avoids overshoot and trims part-load losses.

3) Constraint-Safe Policy Learning

We employ a learning controller that is hard-bounded by safety and comfort constraints. It never violates: freeze protection, max/min SAT, equipment limits, or the operator-approved comfort envelope. Learning occurs inside these bounds.

4) Shadow Mode Before Direct Control

Before writing any points, the policy runs in shadow: it proposes actions, we compare against actual outcomes, and only when accuracy and stability meet thresholds do we elevate to closed-loop control. This preserves operations while building site-specific confidence.

Inefficiency in buildings is not an edge case—it’s the norm. Every day, 15–30% of HVAC energy quietly slips away through control gaps that no traditional system can truly catch. That is money lost, capacity wasted, and carbon unnecessarily emitted.

With A-Control, these losses turn into double-digit savings without new equipment, without disruption, and without sacrificing comfort. At scale, this is not a nice-to-have; it is the fastest, most cost-effective path to efficiency that every building operator can justify.

Company

Ground One Inc. 14F, 16 Maehun-ro, Seocho-gu, Seoul, Republic of Korea

+82-02-2277-1110

info@archflow.ai

Products

Blog

Contact

GroundOne 2025 © Archflow by GrounOne Inc. All rights reserved